Services

Die Attach

Product support from ground-breaking research to demonstration and commercialization

Backend Packaging Opportunities for Academic and Industrial Users

|

|

|

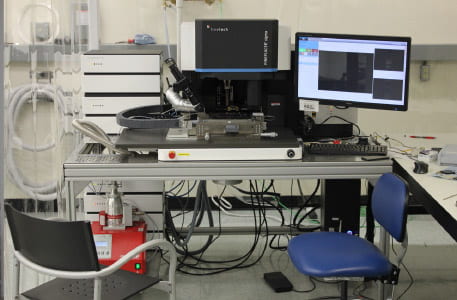

Die attach is the process of electrically connecting an active or passive element to a substrate. Our include attachment via solder paste through a reflow oven, solder preforms through a vacuum oven or with brazing materials in a vacuum furnace for extreme environments. Die can also be connected via gold bumps by ultrasonic agitation.

DIE ATTACH SPECIFICATIONS

- Thermocompression & ultrasonic bonding

- AuSn, eutectic, indium & C4 soldering

- Bump, Cu / Cu, & copper pillar bonding

- Precision vacuum bonding & Sintering

- X/Y placement accuracy: ± 0.5 µm

- Theta placement accuracy: ±0.15o

- Bond force: 500 N

- Built in dispense

- Material holders: Film frame, waffle pack & Gel-Pak

VACUUM SOLDER REFLOW SPECIFICATIONS

- Flux and void free soldering

- 80Au20Sn recipe w/ <1% voiding established

- 95Pb5Sn recipe w/ <10% voiding established

- Vacuum down to 50mTorr

- Gas backfill pressure up to 40 psig

- Operating temperature up to 450°C

- Forming gas (4 to 5% H2/N2) equipped

- Formic acid cleaning step established

- 300mm2 graphite heated working plate

SOLDER REFLOW SPECIFICATIONS

- 125mm wide with clearance up to 75mm

- Tunnel length 125cm with 4 independently controlled heating and 2 cooling zones.

- Maximum temperature of 400°C

- N2 flow controls atmosphere to 15ppm of O2

VACUUM BRAZE SPECIFICATIONS

- Flux and void free soldering

- Glass to metal & glass to glass sealing

- Vacuum down to 100mTorr

- Gas backfill pressure > 40 psig

- Operating temperature up to 700°C

- Forming gas (4 to 5% H2/N2) equipped

- 125mm2 graphite heated working plate